|

Thanks to Ken for his comment. I try to avoid Neil's blog lately. Who wants chipper thoughts when you're slogging through the mire? Wallowing in self pity seems more apropos. We have become accustomed to remanufacturing boat bits (it bites!). Our mire slogging this week turned to finishing the gaffs and tillers and, hmmmmmmmm........................chines! Start drinking now, folks. You'll need it to get through this.

With the first day of autumn at a brisk 96°, we continued on the chines. We did a lot of sanding and the dire premonitions of last week's chine work came to fruition......in spades! It was a lot worse than we thought. One hull had a deep crevasse.

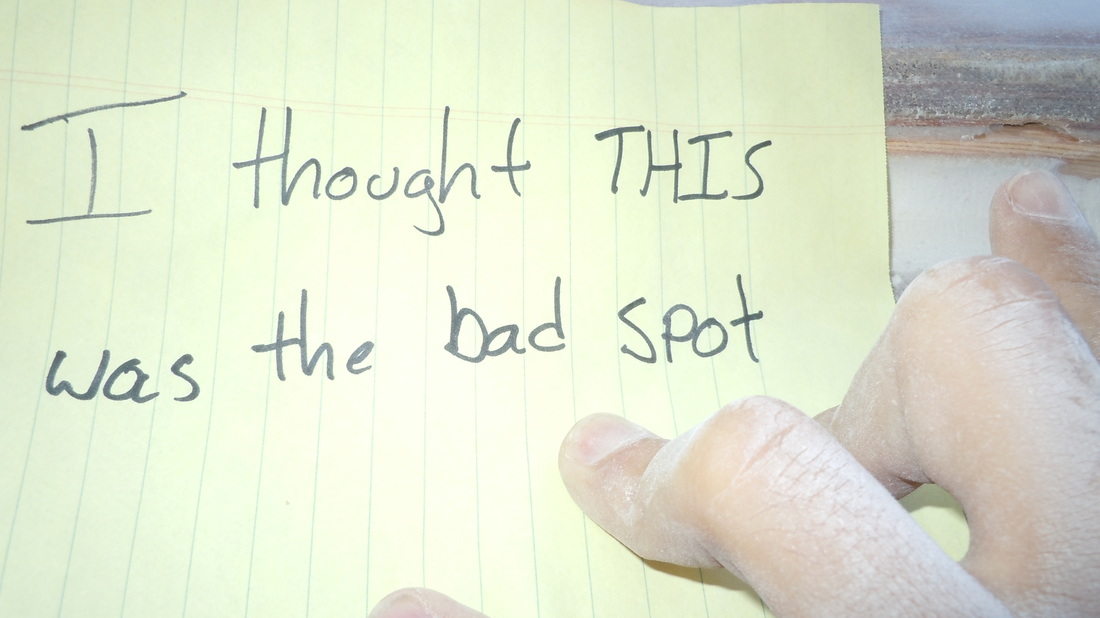

See Bens finger. That spot is a rather large void. These spots required the skills of a master dentist.

So Ben had to take a tool and dig out the bad spots so we could get epoxy into it. They were deep in spots.

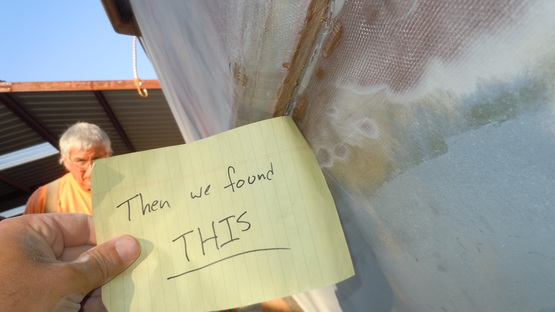

Major problems with the port hull. This is the hull that blew over in a windstorm a couple years back before it was filleted and a complete monocoque. The really bad section required major gouging, epoxy injection and filling before we added the fillets to the chines.

Ben had to dig deep and at one point the plywood had separated from the chine. Injecting low viscosity epoxy deep into the crack was the best we could do.

I could show you this on and on and on. Basically, applied a layer of glass to the strip above the chine and filled the holes and applied a new fillet. We did one side and it went ok. We did one a day. On Wednesday we had a 3 stooges moment. We had to apply glass both above and below the chine on one side of the starboard hull. We were about to start, when Budge and Ben rethought the wheel and decided to discuss the process that we were going to do on the chine. This was basically an "is the candy cane red with white stripes or white with red stripes" discussion. Glass then fillet or fillet then glass. I gave up in disgust as they wasted 20 minutes for 3 people, an entire man hour, during the peak, cool hour of the day. They finally decided (white with red stripes, I think). I sat around and finally gave up and worked on the gaff just to get away from the urination competition. They had to hurry towards the end as the earlier discussion delay pushed the finish time well into the heat of the day. Nyuk nyuk nyuk. When we work in unison, it's beautiful. Process discussions turn into a bad high school debate team .

One gaff bolted together with block. We discussed this: Do you know how many things are complete? None! Every thing we have needs a hole, or a block or a pin or something else, but nothing is completed. I wont show the tillers. Basically I painted them: 2 coats of epoxy, 2 coats of primer, 2 coats of paint, 2 the point of madness!

I also 2, 2, and 2'd the tiller bar. In my spare time (Hah!) I worked the rudder notches.

Then I covered the notches with fiberglass and epoxy. There is only one thing worse than working with epoxy. It's working with epoxy and fiberglass! There is a special place in hell for the people that invented this process, whereas all people that have worked with this stuff will go straight to heaven. They have already been through hell.

They sanded out OK and I started drilling the holes. This was another difficult week. This website kept locking up and was difficult to write under the circumstances. So, for what it's worth, here it is! I cannot say next week will be better.

1 Comment

|

Archives

June 2024

AuthorChuck! Send money! |

The Blog of the Dog.

www.acatnameddog.com

It's important, I think...........

Click the "<<Previous" at the bottom of the page to see the previous week's post.

RSS Feed

RSS Feed