|

Building a boat is not rocket surgery. It is tedium piled upon repetition piled upon monotony ad infinitum until some semblance of a form, resembling a structure that you once conceived of in the far distant past. emerges as a faintly recognizable solidification of your dream. Lost in the depths of your memory and appearing before you, it seems somehow unreal or maybe surreal. Three minds constructing a single object would seem like a juggernaut consortium of skill and knowledge focused lazerlike on the achievement of a goal. It seems, sometimes, that this triumvirate of minds, rather than resembling a troika pulling a sleigh across the steppes, more likely is the spitting image of the three stooges painting a room. Or Ollie and Stan delivering a piano. Such is the rudder problem.

So a long long time ago Budge cut out the rudder shapes. Time passed. The rudders were one of Ben's first projects; back when he thought that "Wharram" was the sound a ricocheting hammer makes when thrown against a galvalume wall. He told Ben just to put them together using a butt joint with cheeks on the side (sounds dirty). Ben didn't know..........................

While evaluating the stern post situation, we dry fit a rudder. We could not do this at all before because the stern post was too close to the rear wall of the shop. Now we were out in the open and...................................

Holy Crap! They were 208 mm (8") too tall. Depression is never far away when building one of these. God bless Canadian Whiskey. The rudders were built wrong (twice!), the stern post was close to 30 mm off, nyuck nyuck nyuck. The Howard brothers are having a grand time looking down from heaven. The two rudder problems had to be solved simultaneously, one process determining the course of action for the other. So, what to do?

So the humidity was fine...................... This was in the shade of the shop on Tuesday. We could cut off the bottom of the rudders.........................mmmmmmmmmmmmmmm, nope. We could cut and reshape the top.............................mmmmmmmmmmmmmmm, nope. Tina Turner once said "we never do anything nice and easy" Such is our lot; I said "We're cutting it out of the middle. Step one: remove the now doubled cheeks.

Cut a whole bunch of saw cuts to the correct depth.

Smash them off with a mallet (see frustration therapy). Make big pile of trash.

Next, chisel, plane, and sand down the very rough area so that we can reassemble (again) the rudders.

Hand planer.

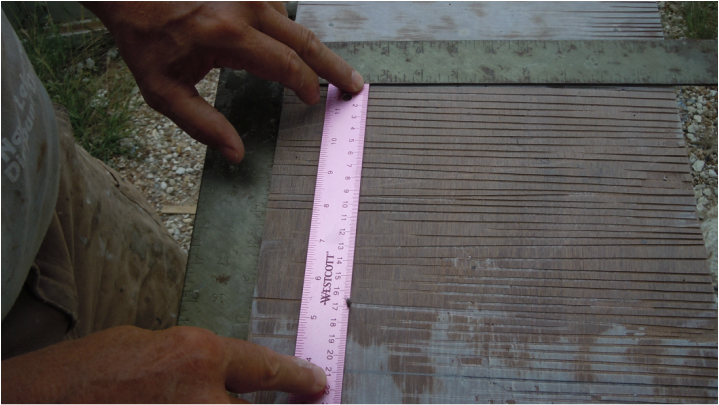

Hand sander. We had to cut off this much:

Betwixt my fingers lies the error of our ways.

So one piece became three. The throw away piece is the top one. Ben and I decided to do it right and make a spline joint to reinforce the repair. I cut the small piece dado on the table saw. The large piece had to be cut another way.

The scary way-with a skill saw? Mmmmmmmmmmmmmmmm....................nope.

Dammit....the slow, difficult and safe way with a back saw. So how in our 20/20 hindsite did we determine what went wrong with this variation on the rudder problem?

Yup, If it had a scarf joint, it would have taken up exactly 208 mm. Now I won't turn this into a rant about the quality of the plans I bought. We have cursed these plans innumerable times and will not pee in your Cheerios if you are an aficionado of this design. I have never worked from plans before, preferring to design my own plans so the process is firmly in my head and not on several sheets of paper placed randomly in a obfuscated, haphazard manor. I will never work from plans again (woops, there goes my endorsement on the official website). So, while I was meandering through the mire, what was Ben up to? I saw him actually throw a tool with as much force a he could muster in frustration about our processes. The only problem was that he had to go and fetch it!

He had to resize the hatch comings because the were designed without taking into account that epoxy coatings and paint (popcorn ball) actually occupy space. The hatches would not fit on the comings (shut up, Curley). After several attempts at planning and sanding, in a brilliant solution achieved through a period of meditation (nap time), I decided to make him a jig to place on the coamings and shave the edges down to size.

With problems with the thin kerf blade, and a mite of assistance from Budge, it worked and, once again, the day was saved ( we are getting mighty sick of these damn saved days). So, amidst all this trial and strife, what was Budge up to: more trial and strife.

Major surgery! Once I decided upon a course of action on the rudders, he was left to no avail but to make the stern correct. The stern post was off by 30 mm and had a twist front to back. He cut off the ply at the rear.

And shaved the stern post to it's essential essence only to allow it to emerge like the phoenix to it's renewed station in the boat. He then constructed a basic triangular top piece to correct the position and twist.

This pulled out the twist and realigned the center of the stern (hey, you're watching genius at work, here!). He then had to lap in stringers to support the repositioned stern.

Glue in the top alignment piece and lap in stringer extensions.

Then glue the stringers to the stem post. He enlarged the access hole so we can get to the stern and squeeze in epoxy. He connected the two circles to make an oblong access hole.

Summertime. The days get longer. The temperature gets hotter. The wildflowers get fewer. The lake level get's lower. The tempers get shorter. The weeds get taller. The bugs get bigger. The bees get buzzier. The sweat gets runnier. Thanks to the folks who made comments on last week's post. And good luck to all those boatbuilders that immediately ran to their boats and snapped a chalk line on their stern posts. We specialize in instilling panic, by example, into the hearts of constructors of watercraft.

Oh, hell, just listen.

2 Comments

|

Archives

June 2024

AuthorChuck! Send money! |

The Blog of the Dog.

www.acatnameddog.com

It's important, I think...........

Click the "<<Previous" at the bottom of the page to see the previous week's post.

RSS Feed

RSS Feed